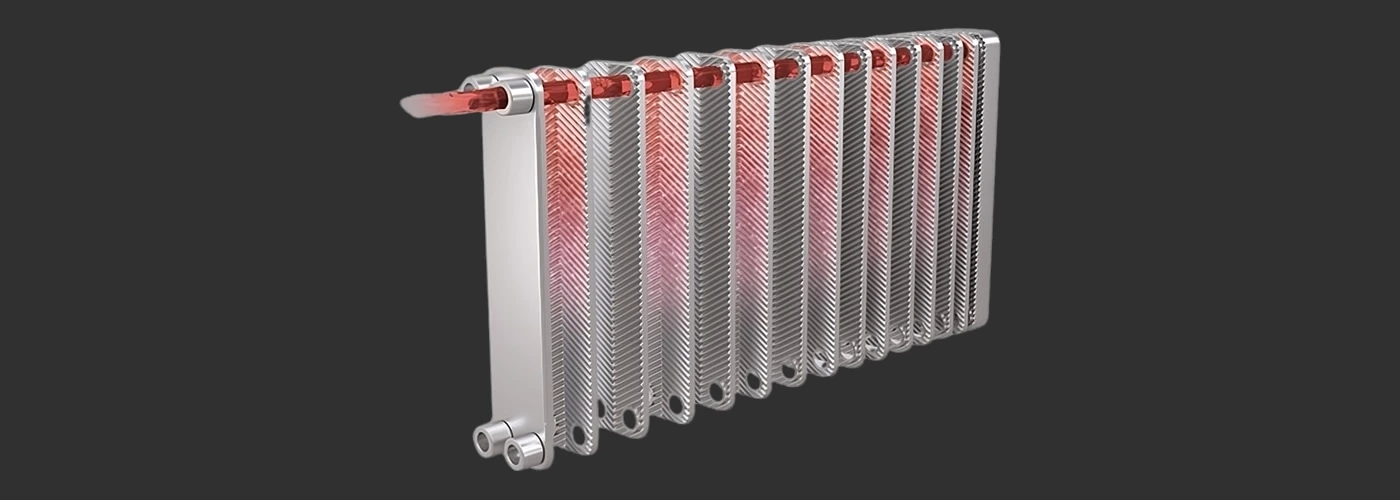

The hygiene and corrosion resistance of all stainless steel fusion welded plate heat exchangers are incomparable to any other brazed plate heat exchanger. Under some extreme temperature changes and pressure fatigue conditions, traditional brazed heat exchangers are not competent, and the emergence of all stainless steel fusion welded plate heat exchangers makes it feasible to use high-efficiency plate heat exchangers under these conditions. Which stainless steel structure allows it to withstand high temperatures up to 550℃.

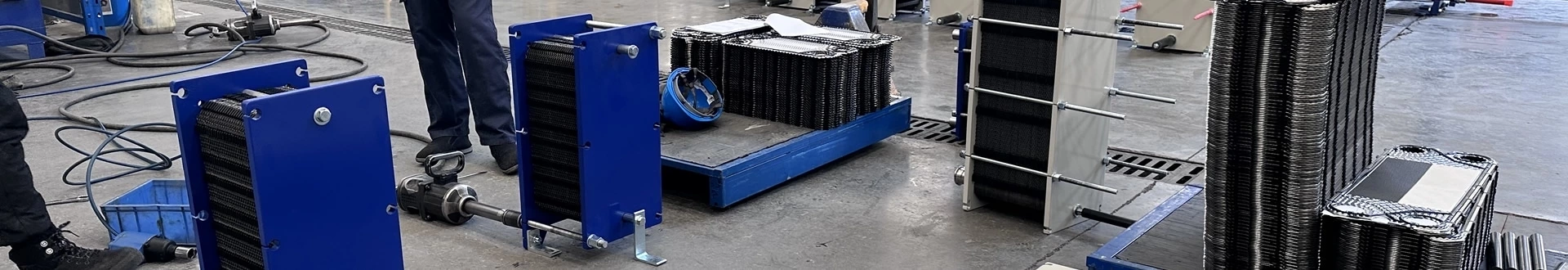

Fusion bonding technology creates highly efficient, compact heat exchangers made entirely of stainless steel. Virtually maintenance free and capable of handling extremely high pressures and temperatures, they are an ideal heat transfer solution for challenging applications. These include duties with high cleanliness demands, with aggressive media such as ammonia, or where copper or nickel pose contamination risks.

Our all stainless steel fusion plate heat exchanger is a breakthrough manufacturing technique that combines improved hygiene and corrosion resistance with the high efficiency and compact footprint of a brazed plate heat exchanger. By enabling a full stainless steel construction, our fusion-bonded heat exchangers can be used in installations normally reserved for conventional semi-welded and welded technologies. They are also a confident choice when the prime focus is on cleanliness, such as in clean water refrigeration and tap water heating systems.

In applications with high hygiene demands, all equipment must conform to the strictest standards. For drinking water applications in particular, where protecting consumer health is a top concern, preventing the possibility of nickel and copper contamination has become a critical issue. As a result, more and more OEMs are seeking heat exchanger solutions for clean water chiller and tap water heating systems that do not use these metals.

Built in 100% stainless steel, our all stainless steel fusion plate heat exchangers are an optimal choice when nickel and copper just won’t do. In addition to providing peace of mind when it comes to hygiene, they also offer much higher efficiency than traditional copper and nickel-free solutions used for these duties.

Interested in learning more? Contact us to get the right solution for you!

Please send your information to us and we will give you feedback in time.