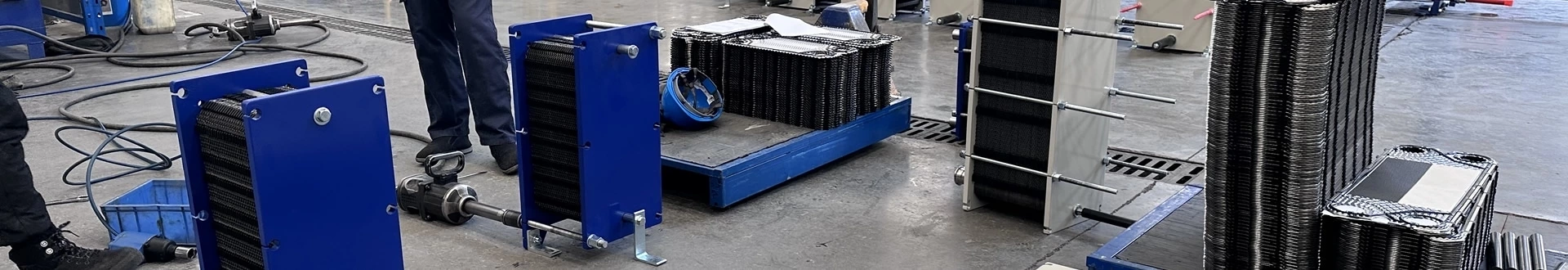

Application Case Analysis Of Fully Welded Plate Heat Exchangers In The Petrochemical Industry

n the field of petrochemical industry, fully welded plate heat exchangers are widely used due to their unique advantages. Here are some specific application case analyses:

Diversified process adaptability:

The oil and gas industry involves various complex process flows, which have different requirements for heat exchange equipment. Due to its flexible design, fully welded plate heat exchangers can be customized according to specific process conditions to meet various process requirements.

The advantages of wide channel design:

For waste heat recovery containing solids, crystals, fibers, slurries, and highly viscous liquids, wide channel fully welded plate heat exchangers demonstrate their superiority. This type of heat exchanger not only has high efficiency and large heat transfer coefficient, but also has small pressure loss, simple structure, and convenient maintenance. Its temperature resistance and pressure resistance performance have also been significantly improved, making it more widely used in the limited application fields of traditional gasket heat exchangers.

Structural advantage:

The structural advantage of fully welded plate heat exchangers lies in the absence of temperature sensitive components such as rubber gaskets, which can operate in high-temperature environments and have good pressure resistance, making them suitable for high-pressure environments. In addition, welded structures provide better corrosion resistance and are suitable for handling corrosive media.

Economic benefits improvement:

In some cases, using fully welded plate heat exchangers in series with existing acidic water heat exchangers can not only bring significant economic benefits but also promote the development of related technologies.

In summary, the application cases of fully welded plate heat exchangers in the petrochemical industry indicate that their structural characteristics and performance advantages make them an effective tool for solving heat exchange problems under complex process conditions. Through continuous technological innovation and optimized design, fully welded plate heat exchangers will continue to play an important role in the petrochemical industry.

Welcome To Visit Our Official Website!

If you have any questions, please contact us through the following ways, we will give you the most sincere service!