Performance And Characteristics Of Fully Welded Plate Heat Exchangers

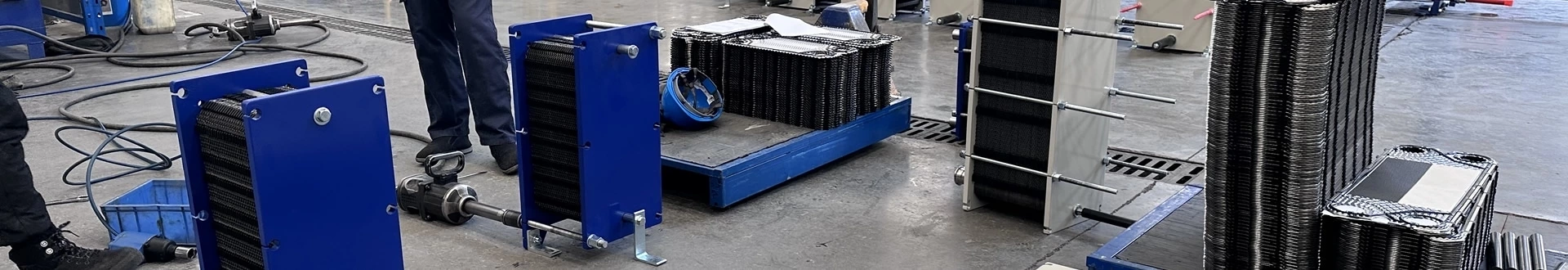

The fully welded plate heat exchanger is an efficient heat exchange equipment that uses special stainless steel heat exchange plates, which are pressed by special molds. Its heat transfer efficiency is high, and strong turbulence can be generated at lower flow rates, fully exerting its heat transfer ability and achieving high heat transfer performance. Compared with shell and tube heat exchangers, the total heat transfer coefficient is 3-5 times that of shell and tube heat exchangers; Under the same heat transfer conditions, its heat transfer area is only 1/3 to 1/4 of that of the shell and tube type; In addition, the fouling coefficient of fully welded plate heat exchangers is only 1/5 of that of tubular heat exchangers, indicating excellent heat transfer performance.

Secondly, the fully welded plate heat exchanger has a special fully welded process that does not require non-metallic materials for sealing. Its structural design is diverse and can be applied at higher temperatures and pressures. In addition, the special plate ripple structure fills the flow channel formed between the plates with fluid, and all plate surfaces participate in heat exchange. The medium can achieve dead zone free flow in the flow channel, which can reduce the consumption of kinetic energy to a certain extent and save operating costs.

Finally, the fully welded plate heat exchanger has a compact structure and a small footprint. This high-efficiency heat exchange equipment combines the advantages of plate heat exchangers and shell and tube heat exchangers. On the one hand, it retains the high efficiency and compact structure of plate heat exchangers, and on the other hand, it combines the high temperature and high pressure resistance of shell and tube heat exchangers. It is the most ideal equipment to replace shell and tube heat exchangers in some special heat exchange processes. Therefore, fully welded plate heat exchangers are widely used in heating, cooling, condensation, evaporation and other processes in fields such as chemical, petroleum, power, and metallurgy.

Welcome To Visit Our Official Website!

If you have any questions, please contact us through the following ways, we will give you the most sincere service!