What you need to know about fully-welded plate heat exchangers?

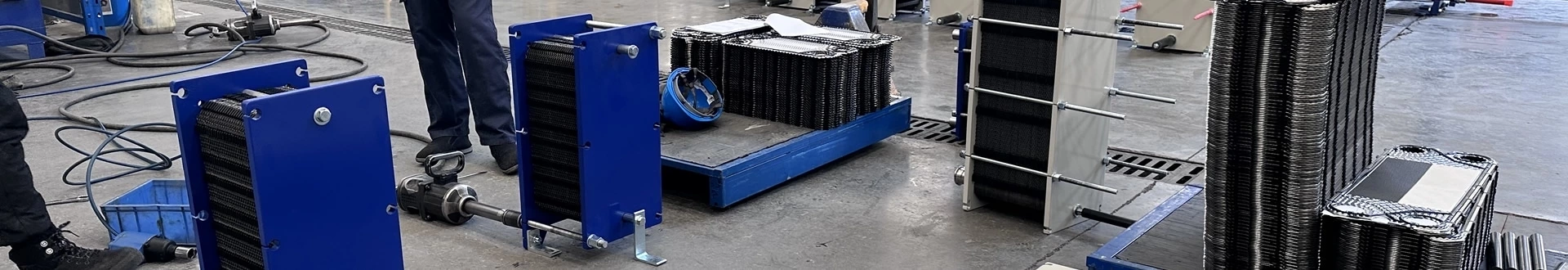

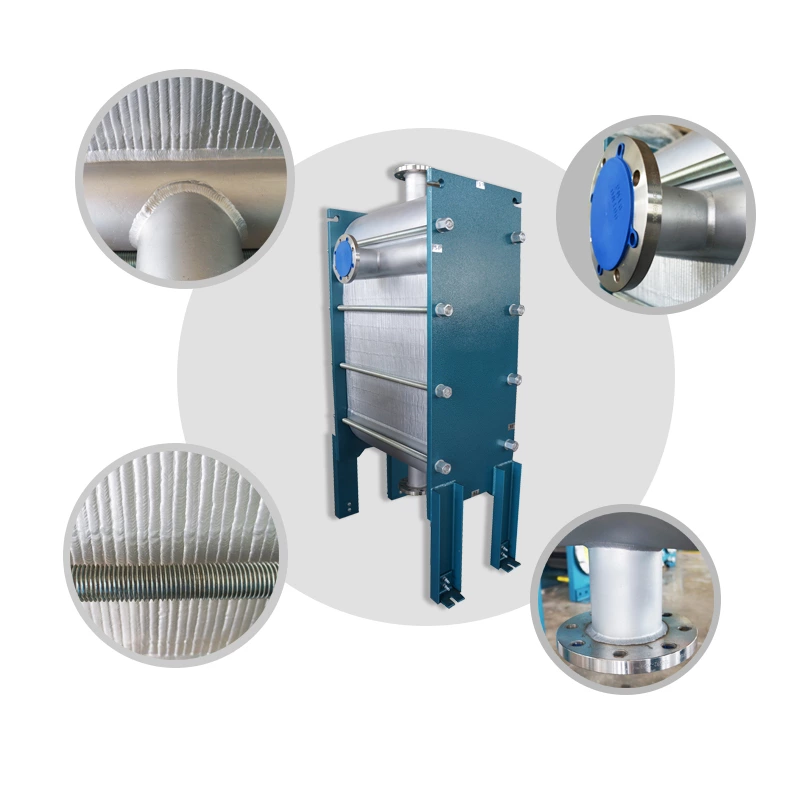

1. Fully-welded plate heat exchanger features

The main feature of the fully-welded plate heat exchanger is its structure of fully-welded design. Compared with the traditional heat exchanger, fully-welded heat exchanger adopts a seamless welding method, without the traditional heat exchanger sealing gasket, thus greatly reducing the risk of leakage. The fully-welded structure also has good corrosion resistance and can adapt to complex working environments. In addition, the fully-welded heat exchanger has high strength and stiffness and can withstand high working pressure.

2. Fully-welded heat exchanger’s application

Fully-welded heat exchanger has a wide range of applications. In the petrochemical field, which can be used in crude oil cooling, distillation tower condensation, solvent recovery and other processes, can effectively improve production efficiency and product quality. In the electric power industry, which is widely used in thermal power generating units in the waste heat recovery system, can use the flue gas waste heat to provide other equipment for energy supply, to achieve energy recycling. In addition, fully-welded heat exchanger is also used in metallurgy, pharmaceutical, chemical fertilizer and other industries in the waste heat recovery of exhaust gas, to achieve the goal of energy saving and emission reduction.

3. Fully-welded heat exchanger's price

Fully-welded heat exchanger's price is relatively high, but its high efficiency of heat transfer and long service life makes it in some special occasions still has a high cost-effective. In addition, which has low maintenance costs, no need for frequent replacement of sealing gaskets, reducing the maintenance work of the staff. Fully-welded heat exchangers remain a viable option when considering equipment stability and long-term operating and maintenance costs.

Overall, fully-welded heat exchanger, as a kind of high efficiency heat exchange equipment with corrosion resistance, high strength, energy saving and emission reduction, is widely used in chemical, petroleum, electric power, metallurgy, pharmaceutical and other fields. Although the price is relatively high, but in some special occasions still has a high cost-effective. The emergence of fully-welded heat exchangers provides convenience for industrial production, and also makes a positive contribution to energy saving and emission reduction.

Welcome To Visit Our Official Website!

If you have any questions, please contact us through the following ways, we will give you the most sincere service!