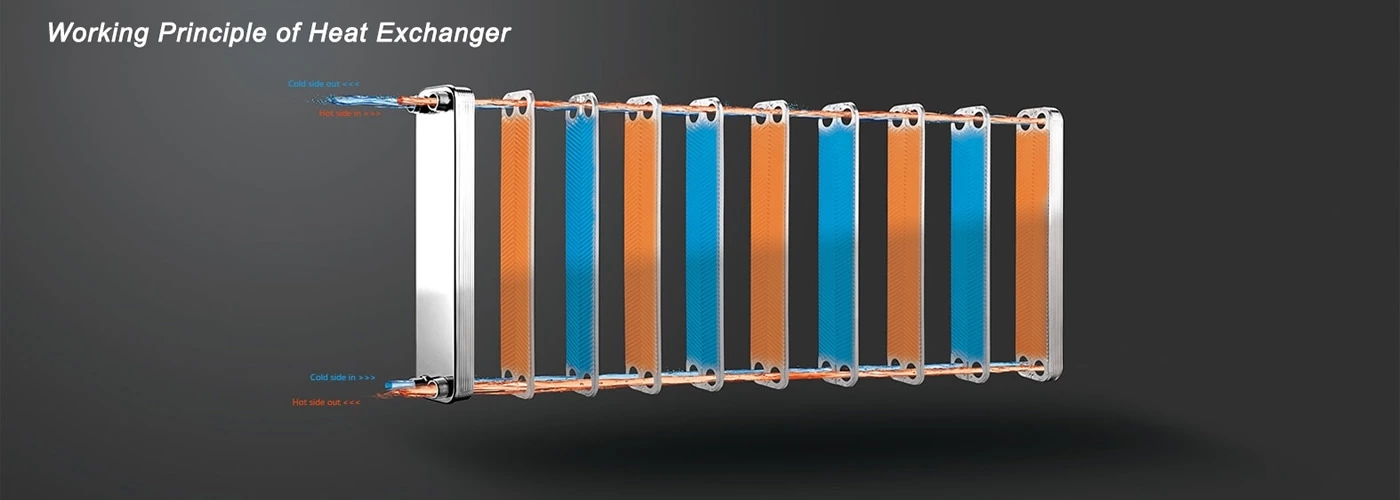

Brazed plate heat exchanger is a type of heat exchanger made by pressing stainless steel sheets into heat exchange plates with a certain ripple shape, then stacking and brazing them in a vacuum brazing furnace. A cold and hot fluid flow channel is formed between each plate, and the cold and hot fluid flows through the channels on both sides of the corrugated plate and exchanges heat. This structure and heat exchange principle determine that brazed plate heat exchangers have the characteristics of compact structure, small footprint, high heat transfer efficiency, strong operational flexibility, wide application range, low heat loss, and convenient installation and cleaning. A brazed plate heat exchanger (BPHE) is also known as a brazed heat exchanger.

Brazed Plate Heat Exchangers can be used for a range of functions in a heating or cooling system – they can act as condensers, evaporators, oil or gas coolers, and be used for other functions that involve the transfer of heating or cooling. BPHEs are widely used in a range of applications such as HVAC, refrigeration, industrial processes, electric vehicles (EV) and renewable energy systems, etc.

OUDUN brazed heat exchanger is a compact and efficient solution, can be used for a variety of applications in the heating, cooling, evaporation and condensation. Each product are for the heat transfer condition of demand optimization design, has the function of a series of unique to ensure good thermal performance and reliability. Even in the design of high pressure conditions, also can achieve a long service life.

Firm structure and reliable, complete specifications and broad, OUDUN brazed heat exchanger to provide you with the wise choice to replace the traditional heat exchangers. OUDUN heating and refrigeration expert experience combined with our constant innovation in design and manufacturing technology, can ensure that you always can get the most competitive solution.

A brazed plate heat exchanger (BPHE) is utilized for its high heat transfer efficiency, compact size, and cost-effectiveness. It offers versatility, quick response times, and easy maintenance. These advantages make BPHEs an excellent choice for various applications, including HVAC, refrigeration, electric vehicles(EV) and more.

Durable and highly corrosion-resistant - made of SUS316 material plates by copper or nickel welding. Provide high corrosion resistance characteristics for various fluids.

High pressure resistance - The vacuum brazing process enables the plate heat exchanger to achieve a pressure resistance to 45 bar.

Excellent heat transfer effect - Specially designed plate patterns can achieve higher heat transfer efficiency under both countercurrent flow and parallel flow conditions.

High temperature resistant - The SUS316 material of the brazed plate heat exchanger allows its operating temperature to reach up to 200℃.

Compact, convenient, and lightweight - brazed plate heat exchangers are lighter and more convenient than shell and tube heat exchangers; Under the same heat transfer capacity, it is only 1/5 of the size of the shell and tube type,. And it is more convenient to install and replace.

Low maintenance cost - The specially designed plate pattern is fully suitable for heat transfer turbulent flow situations, no need to special and frequent maintenance.

Cost-effective – You will save on energy, maintenance, spare parts, and installation. The life-cycle cost over 15-20 years can often be half that of a corresponding gasket solution.

Customized – By combining plate design, materials, and connections from standard components, we keep lead times short while still maximizing output in your specific application. Fill out our Specification Form below to fulfill your requirement now!

Heat pumps, water coolers, oil coolers, injection molding machines, air conditioners, freezers, air dryers, water cooling, constant temperature cold storage, low-temperature testing rooms, waste heat recovery, wall mounted boilers, underfloor heating, centralized heating, superheat, hydraulic machinery, wind power generation, automotive hydraulic systems, hot water systems, heating systems, cleaning systems, etc.

Please send your information to us and we will give you feedback in time.