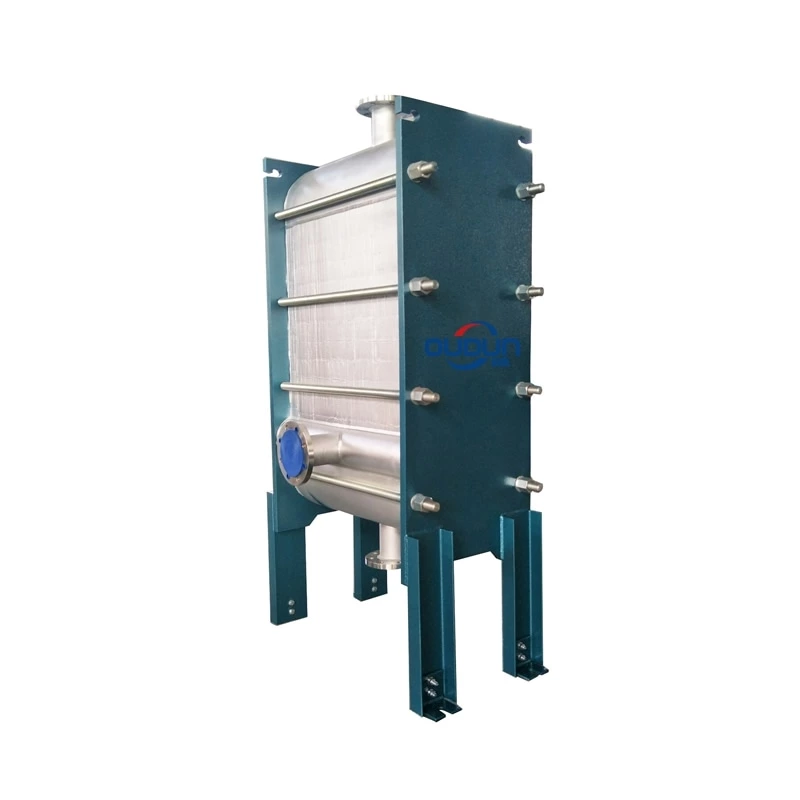

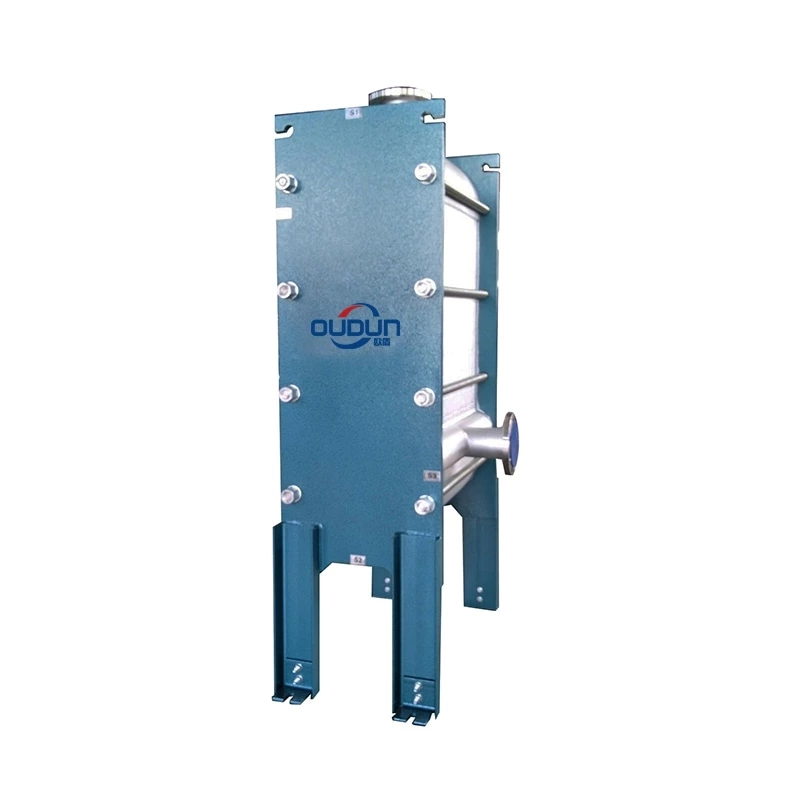

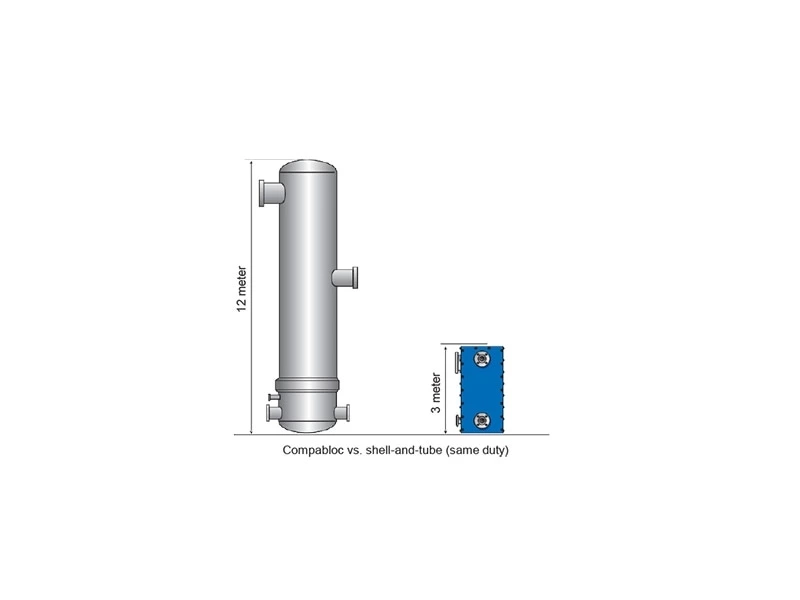

The fully welded plate heat exchanger is a new type of high-efficiency heat exchange equipment that absorbs the advantages of gasketed plate heat exchanger and compensates for the shortcomings of shell & tube heat exchanger. It completely eliminates the gasket on the basis of the original semi welded plate heat exchanger and can be used in medium pressure and medium temperature applications. It retains the full counter current heat transfer characteristics of a gasketed plate heat exchanger, which is 3-5 times more efficient than traditional shell & tube heat exchanger. According to the application requirements, the plate and frame type can be divided into: non-detachable fully welded plate heat exchangers, 2-sided detachable fully welded plate heat exchangers, 4-sided detachable fully welded plate heat exchangers (HFM bloc), and wide channel fully welded plate heat exchanger..

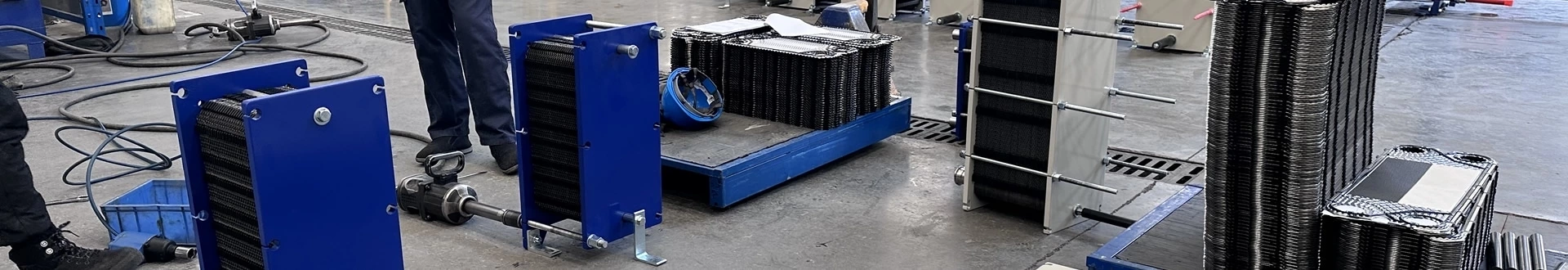

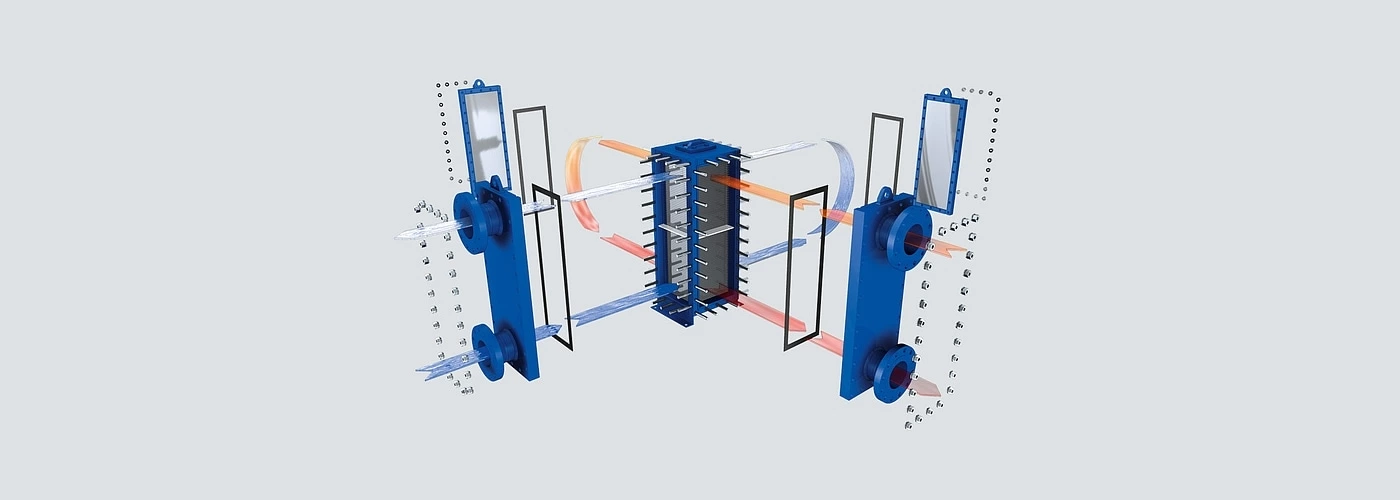

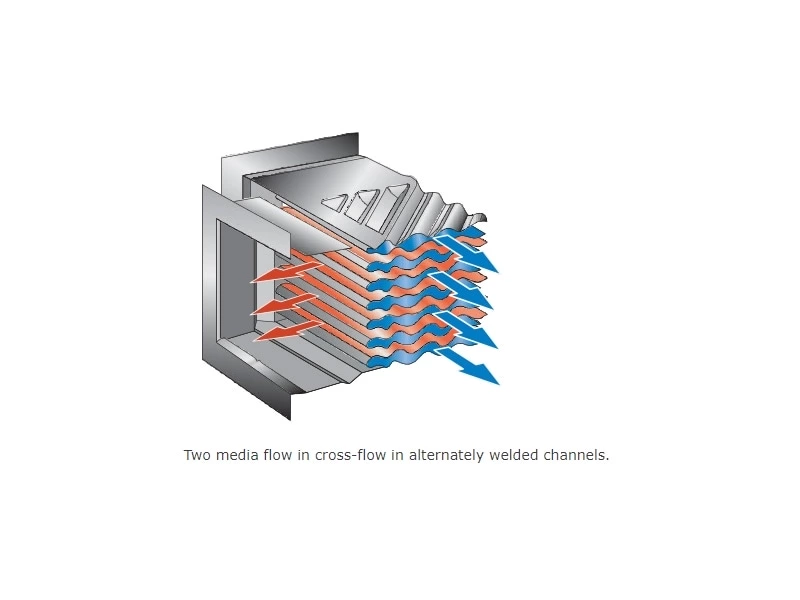

The two media in the fully welded plate heat exchanger flow in alternately welded channels between the corrugated plates.

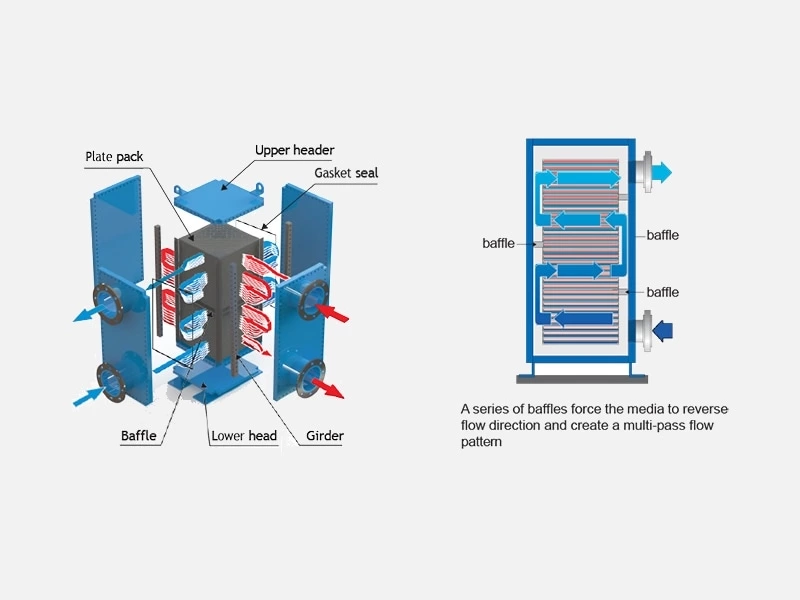

These corrugated plates promote high turbulence which provides high heat transfer efficiency and help minimize fouling. The media flows in a cross-flow arrangement within each pass while the overall flow arrangement is counter-current for a multi-pass unit (if required the unit can also be designed with overall co-current operation). Each pass is separated from the adjacent passes by a pressed baffle which forces the fluid to turn between the plate pack and the panel.

Fully welded flexible pass arrangements make it suitable for liquid to liquid duties with dissimilar flow rates, or two phase condensation or reboiler application.

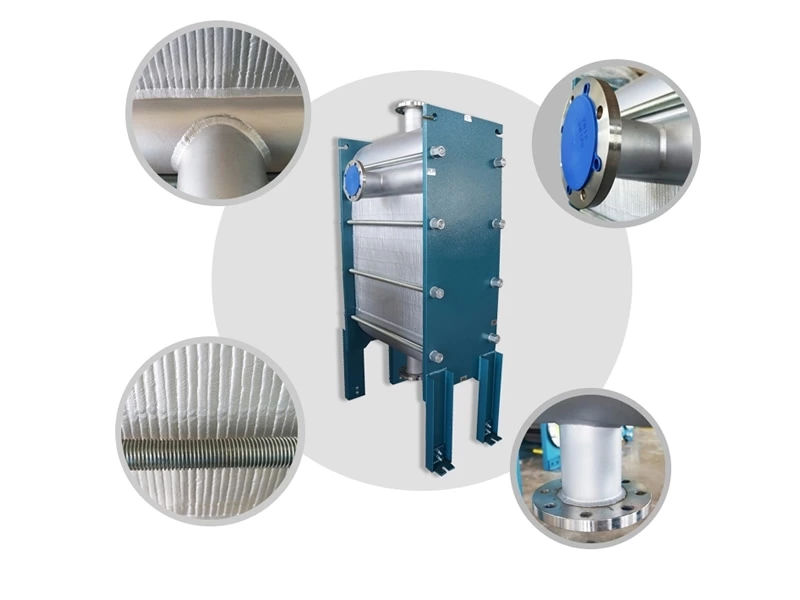

Stainless Steel: 304L, 316L, 904L

Special Metals: 254SMO, Hastelloy 276, Titanium, Nickel200/201, etc.

Plate Thickness: 0.8mm-1.2mm

Design Pressure: Max 40bar

Design Temperature: -196° to 400°

Please send your information to us and we will give you feedback in time.