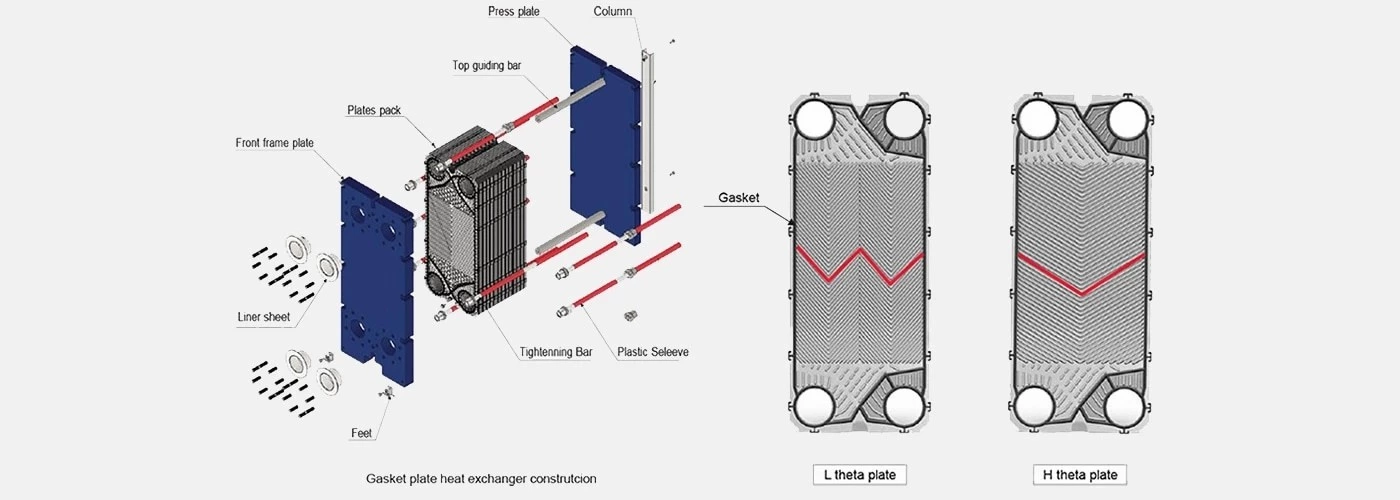

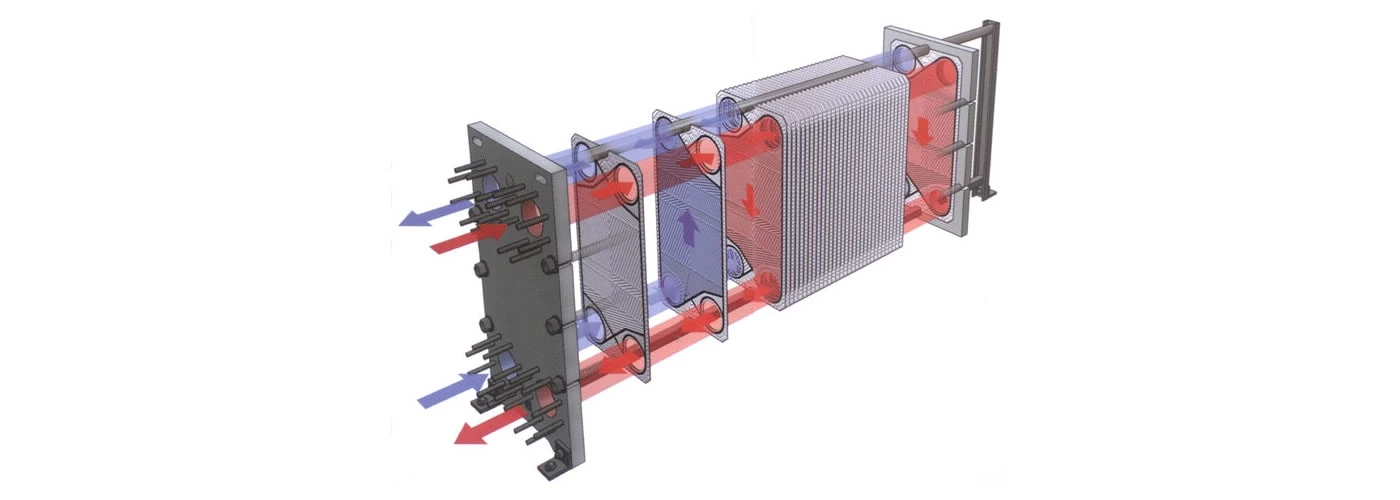

Gasketed plate heat exchanger is composed of many corrugated metal sheets stamped at certain intervals, sealed with gaskets around them, and overlapped and compressed with frame and compression bolts. The four corner holes of the plate and gasket form the distribution and collection pipes for the fluid, while also reasonably separating the cold and hot fluids, allowing them to flow separately in the flow channels on both sides of each plate and conduct heat exchange through the plate.

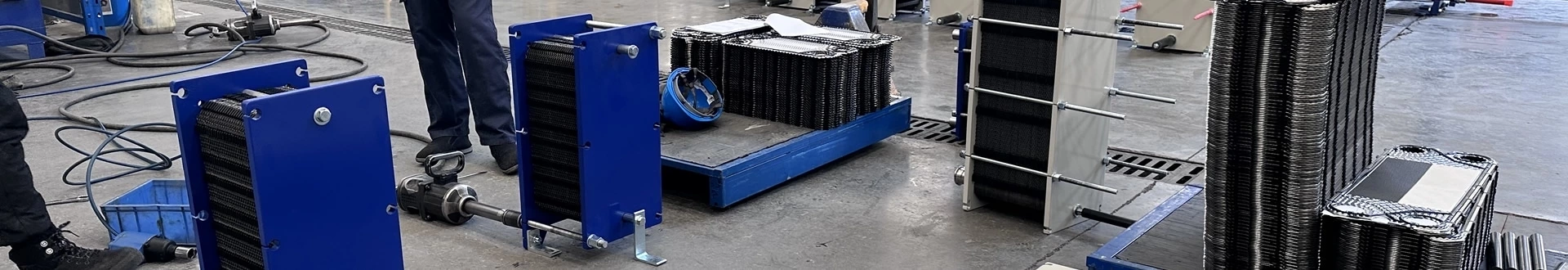

The turbulence caused by corrugated plates as fluids course through the assembly increases the effective heat transfer coefficient, enabling efficient thermal exchange. OUDUN has an extensive range of plate heat exchangers designed for various industries and applications, catering to heating, cooling, heat recovery, condensation, and evaporation.

The application of heat exchnager can be found across industrial engineering applications such as refrigeration, airconditioning systems, power plants, food processing systems, chemical processing plant and automobile radiators.

The most common heat exchanger in industry is the plate heat exchanger. Plate heat exchangers are essential equipment that plays a critical role in various industrial processes, enabling the efficient and effective transfer of heat between different mediums.

Gasketed Plate Heat Exchangers (GPHEs) are designed to optimize heat transfer between two fluids or gases. The corrugated plates within the Gasketed Plate Heat Exchanger allow for efficient heat transfer from one medium to the other.

The plates used in Gasketed Plate Heat Exchanger are equipped with elastomeric gaskets that seal the channels and direct the mediums into alternating channels. The plate pack is placed between a frame plate and a pressure plate and compressed using bolts between the plates.

An upper carrying bar supports the channel and pressure plate, which are then fixed in position by a lower guiding bar on the support column. This design facilitates easy cleaning and modification by adding or removing plates.

| Plate Material Characteristics | ||||

|---|---|---|---|---|

| Material | Application | |||

| SS304 | Drink water, None Corrosive Liquid, Oils, Fresh Steam etc. | |||

| SS316L | Well water, river water, closed circulating water and other water with complex components, Dilute sulfuric acid with temperature ≤ 50 ℃ and concentration ≤ 10% etc. | |||

| Titanium | Liquid that contains chlorine iron, Sea water etc. | |||

| Titanium Palladium Alloy | Higher temperature and corrosion resistance than titanium. | |||

| Nickel 20 | It is mainly used for caustic solution (NaOH, Koh, etc.) with high concentration (50% ~ 70%) and high temperature (boiling point). | |||

| 254SMO | Saline, Inorganic acid | |||

| Hastelloy C-276 | It has good corrosion resistance, almost not affected by Cl -, excellent corrosion resistance to various concentrations of sulfuric acid, and is one of the few materials that can be used in hot concentrated sulfuric acid, widely used in organic acids (such as formic acid, acetic acid), high temperature HF acid and a certain concentration of hydrochloric acid (< 40%), phosphoric acid (< 50%); chloride, fluoride. | |||

| Common Gasket Material Charactristics | ||||

|---|---|---|---|---|

| Material | Working Temperature | Working Condition | ||

| NBR | -10~110℃ | Alkane, olefin and other non-polar media, all kinds of mineral oil, animal and vegetable oil, hot water, salt water, etc。 | ||

| HNBR | -10~150℃ | Crude oil, sulfur-containing oil and organic sulfur compounds, some heat transfer oil, new refrigerant 134A, etc | ||

| EPDM | -15~150℃ | Superheated water, steam, atmospheric ozone, non petroleum based lubricating oil, weak acid, weak base, ketone alcohol, etc | ||

| Viton A | -10~160℃ | Nonpolar mineral oil, sulfuric acid, chlorine water, phosphate with concentration above 98% | ||

| Viton G | 0~200℃ | Nonpolar mineral oil, high temperature water vapor, sulfuric acid, chlorine water, phosphate with concentration above 98% | ||

High heat exchange efficiency and low operating cost – Compared with shell-and-tube heat exchanger, its heat exchange effect is 3-5 times.

Compact design – Small footprint.

Easy to install – Occupying only 1/5 to 1/8 of the space required by shell-and-tube heat exchanger.

Convenient maintenance – Easy to disassemble and clean.

Convenient expansion – Open the heat exchanger to increase the number of plates.

Please send your information to us and we will give you feedback in time.