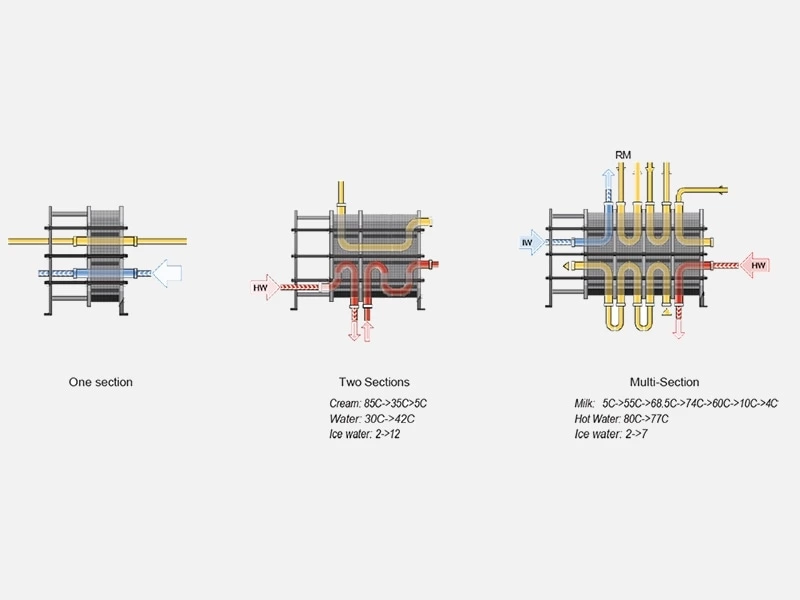

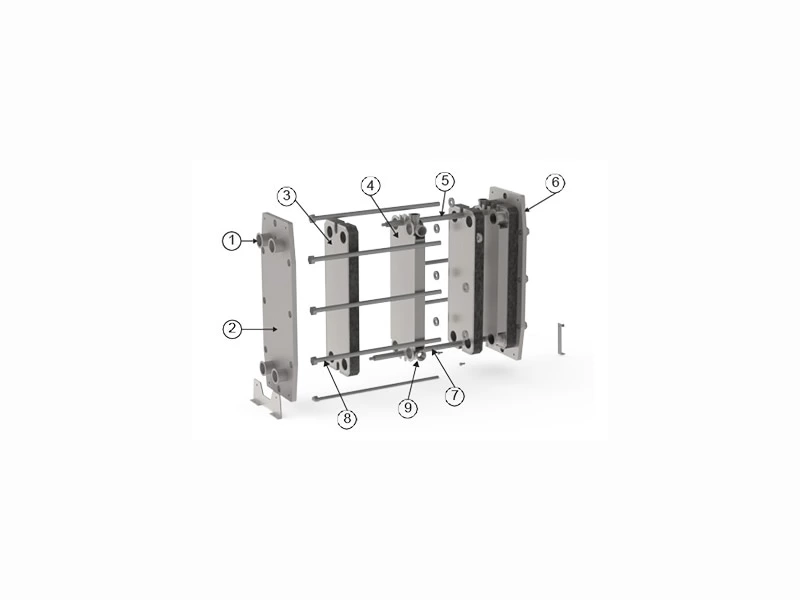

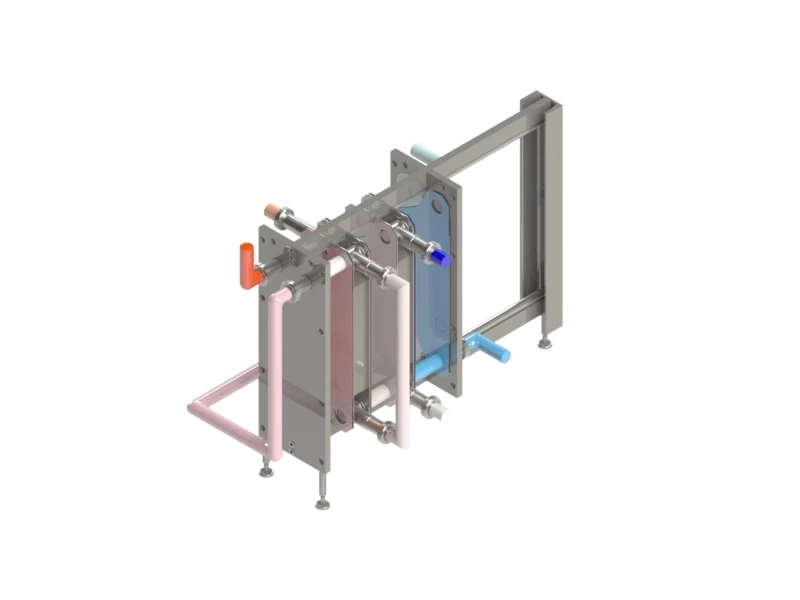

Multi-section plate heat exchanger is also a kind of gasket plate heat exchanger. The multi-section plate heat exchanger can be used for heating and cooling two or more media, usually sectioned by an intermediate partition, and can be constructed into two, three, or four sections, etc. The intermediate partition plate has connection holes for passing the medium. Usually, the intermediate partition material is 304 or 316.

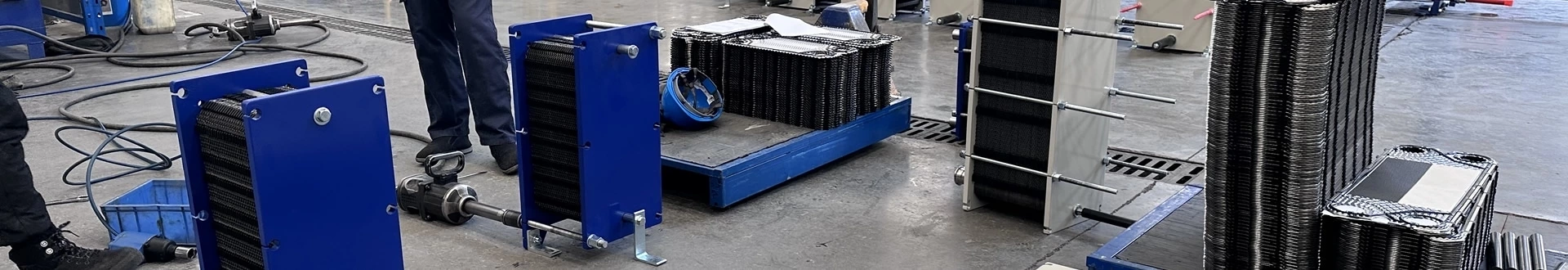

Multi-section plate heat exchanger has plates and rubber gaskets that meet the food grade requirements, and the parts in contact with the medium are all made of stainless steel, and the frame can also be made of stainless steel. It is the hygienic plate heat exchanger.

In a multi-section plate heat exchanger, multiple sets of plates are arranged in sections, allowing for greater flexibility and control over the heat transfer process. Each section can be designed to optimize heat transfer for a specific application or to accommodate different flow rates and temperatures.

Multi-section plate heat exchangers are commonly used in a variety of industrial and commercial applications, including heating and cooling systems, chemical processing, and food processing. They are highly efficient and compact, making them a popular choice for applications where space is limited or where energy efficiency is a top priority.

Plate Material: mainly 304,316L

Plate Thickness: 0.5mm-0.6mm

Frame Material: CS, CS coated with 304 / 316 & Pure stainless steel 304 / 316

Material of intermediate partition: Stainless steel 304 / 316

Gasket Material: NBRF,NBR-HTF,EPDM

Design Pressure: 10bar

Design Temperature: -20℃ to 150℃

Please send your information to us and we will give you feedback in time.