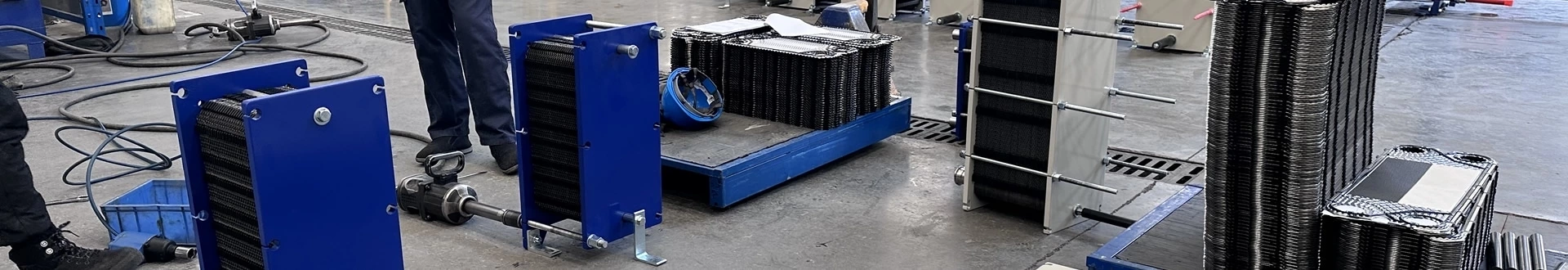

Plate evaporator is an evaporation device that mainly uses metal plates as heat transfer elements.

This type of evaporator is usually composed of a series of thin metal plates, with channels or passages between them, through which the liquid to be evaporated flows.. Plate evaporators are widely used in various industrial fields, such as sugar making, fruit juice, dairy products, bone soup, fermentation, etc., due to their high heat transfer efficiency, compact structure, easy expansion, easy cleaning and maintenance. They can efficiently evaporate liquids at low temperatures, achieve separation and concentration of liquid mixtures, and also have advantages such as energy conservation and easy automation control. In addition, the plates of plate evaporators are usually designed with corrugated grooves to enhance turbulence and improve heat transfer efficiency. The sealing between plates is usually achieved by using sealing gaskets at the edges to ensure smooth passage of the medium flow channel.

The most common metals used in plate evaporators are stainless steel, titanium, and nickel alloys, which are chosen for their resistance to corrosion and durability. They are arranged in a way that creates a series of parallel channels. It is designed to take advantage of the large surface area of thin plates to maximize the transfer of heat from a hot fluid to a cold fluid.

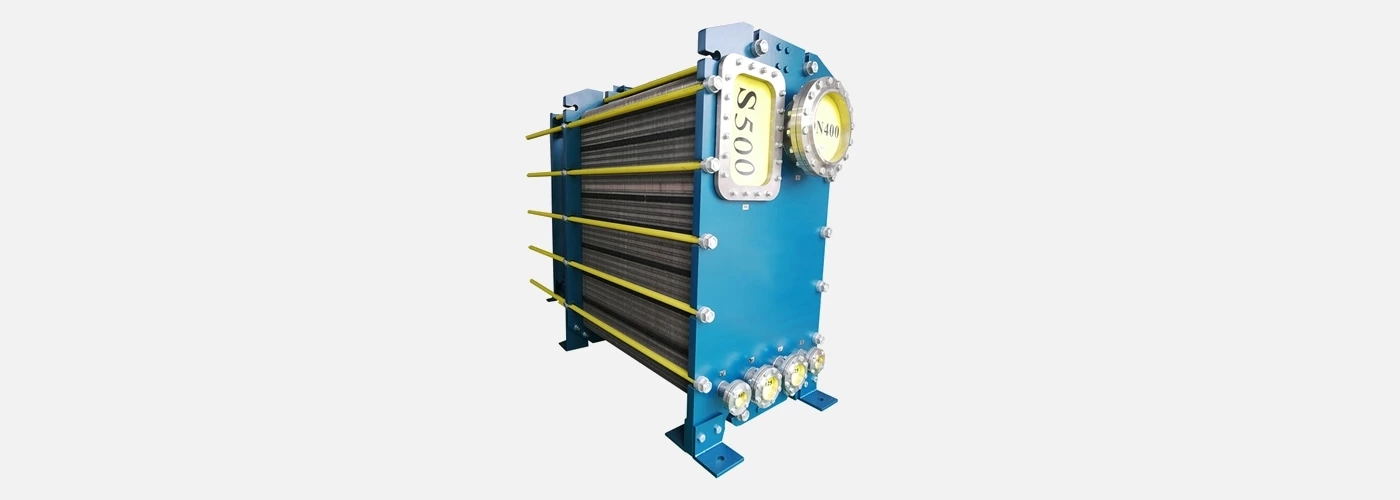

Its design provides higher thermal efficiency than the traditional shell-and-tube evaporators and because of this much less heat transfer area is needed. Plate Evaporator are cost-efficient especially when special metal materials are required.

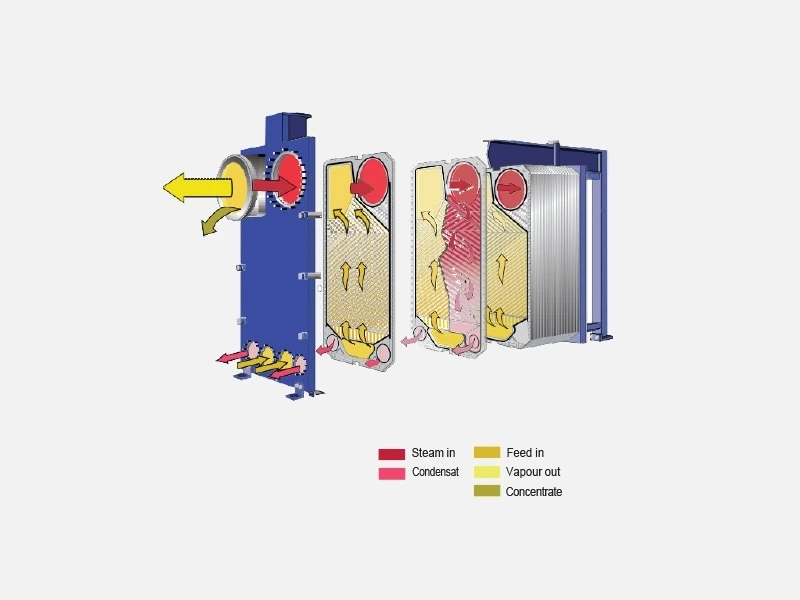

Plate Evaporator is purpose built for evaporation, featuring two compact inlet feed connections and a spacious outlet dedicated to vapor and concentrate. It is equipment with one sizable inlet and two smaller outlets for condensate. The design of Plate Evaporator incorporates plates welded in pairs, allowing for effective condensation of heating steam in the welded channel, while the evaporated product smoothly flows through the gasketed channels.

During operation, the hot fluid flows through the wider channels from the bottom of the evaporator plates, while the liquid being evaporated flows through the narrow channels. Heat is transferred from the hot fluid to the liquid through the evaporator plates, causing the liquid to evaporate and the hot fluid to cool down.

It is commonly used in the food, beverage, and pharmaceutical industries for applications such as concentrating juices, syrups, and other liquids. They are also used in chemical and petrochemical plants for various evaporation and concentration processes.

Plate evaporator is an evaporation device that mainly uses metal plates as heat transfer elements.

This type of evaporator is usually composed of a series of thin metal plates, with channels or passages between them, through which the liquid to be evaporated flows.. Plate evaporators are widely used in various industrial fields, such as sugar making, fruit juice, dairy products, bone soup, fermentation, etc., due to their high heat transfer efficiency, compact structure, easy expansion, easy cleaning and maintenance. They can efficiently evaporate liquids at low temperatures, achieve separation and concentration of liquid mixtures, and also have advantages such as energy conservation and easy automation control.

In addition, the plates of plate evaporators are usually designed with corrugated grooves to enhance turbulence and improve heat transfer efficiency. The sealing between plates is usually achieved by using sealing gaskets at the edges to ensure smooth passage of the medium flow channel.

Efficient heat transfer - Arranged in a way that maximizes heat transfer and minimizes temperature difference between two fluids, resulting in a more efficient evaporation process.

Flexible capacity expansion - One prominent advantage of plate evaporator is its capability to increase or decrease capacity by adding or removing plates within the existing framework. This feature stands in stark contrast to shell & tube evaporators, where capacity remains fixed upon installation.

Energy Efficient - Plate evaporators are designed to minimize heat loss, which makes them more energy efficient than other types of evaporators.

Saving - The remarkable heat transfer efficiency translates into a substantial reduction in required heat transfer surface area compared to shell & tube evaporators. Consequently, plate evaporator becomes highly cost-effective, especially when dealing with demanding materials like SMO, titanium, nickel and Hastelloy.

Additionally, the compact and adaptable design of plate evaporator greatly diminish- es expende related to transportion, assembly, and installation when compared to shell & tube evaporators.

Multiple models provide the best choice - In OUDUN, we have multiple models that are suitable for various working conditions selection.

Plate: 316 / 316L, 904L, SMO254, Ni, Ti, Hastelloy C-276

Gasket: NBR, EPDM, FKM

Please send your information to us and we will give you feedback in time.