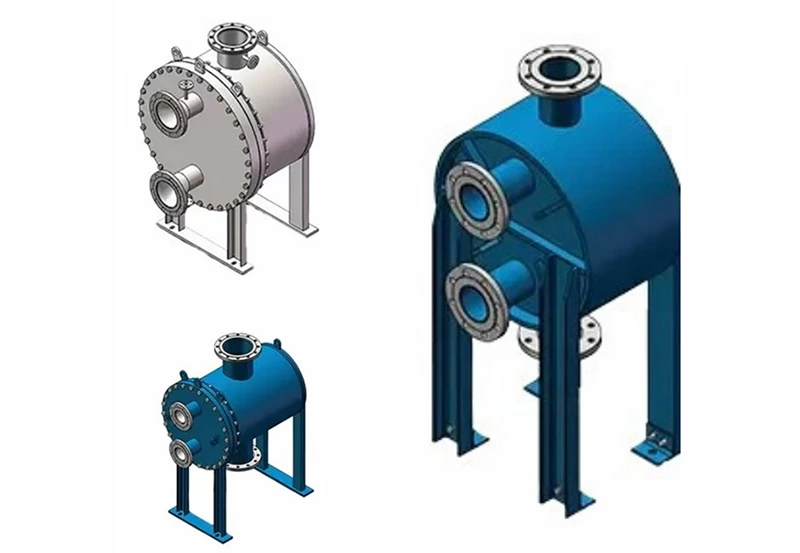

The plate and shell heat exchanger can be also known as the shell and plate heat exchanger or the plate shell heat exchanger. It is a modern plate type heat exchanger that utilizes a group of corrugated plates that are laser or automatically plasma welded into the shell as opposed to the conventional heat exchange tubes of the shell and tube heat exchanger.

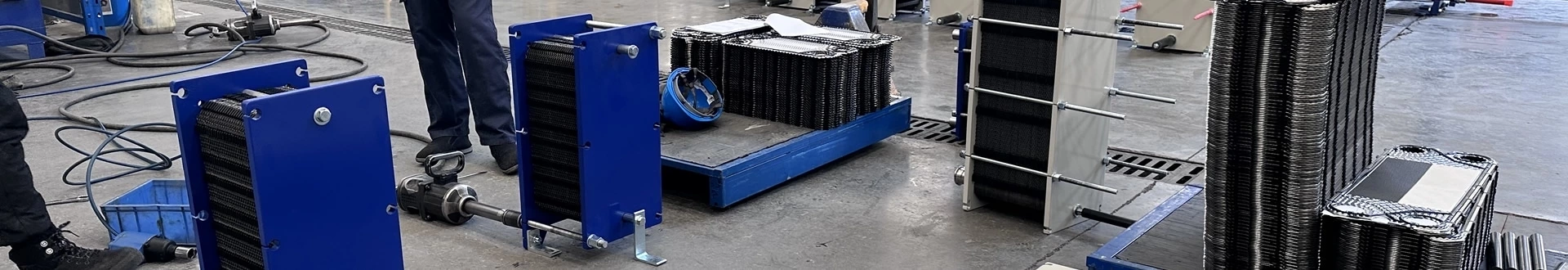

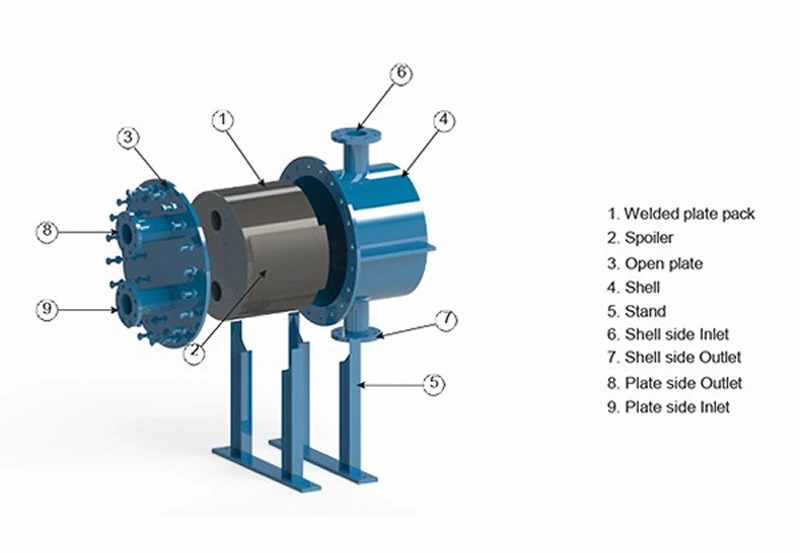

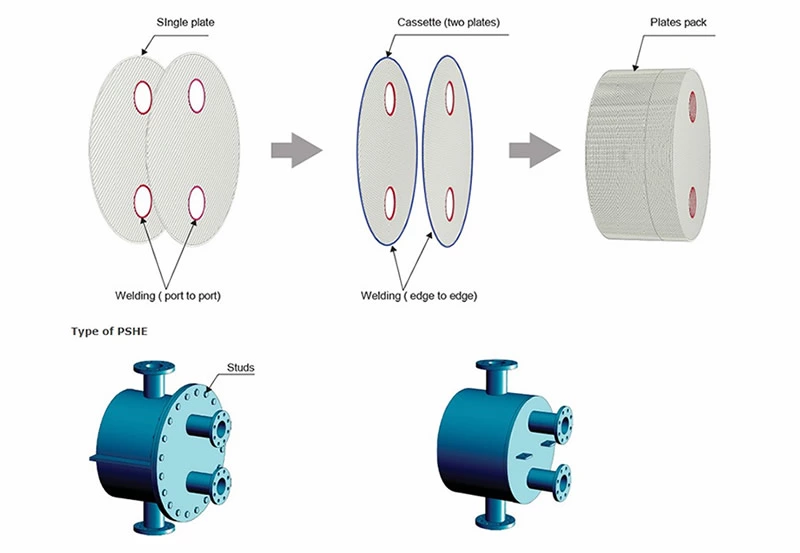

The heat transfer element comprises two components, namely the plate group, and the shell. The plate group contains a stack of closely spaced parallel plates, similar to those found in a plate heat exchanger. These plates are typically made of stainless steel and are designed to create high turbulence and efficient heat transfer. The plate group is fabricated by laser or automatic plasma welding cold-pressed plates together to create two distinct medium flow channels.

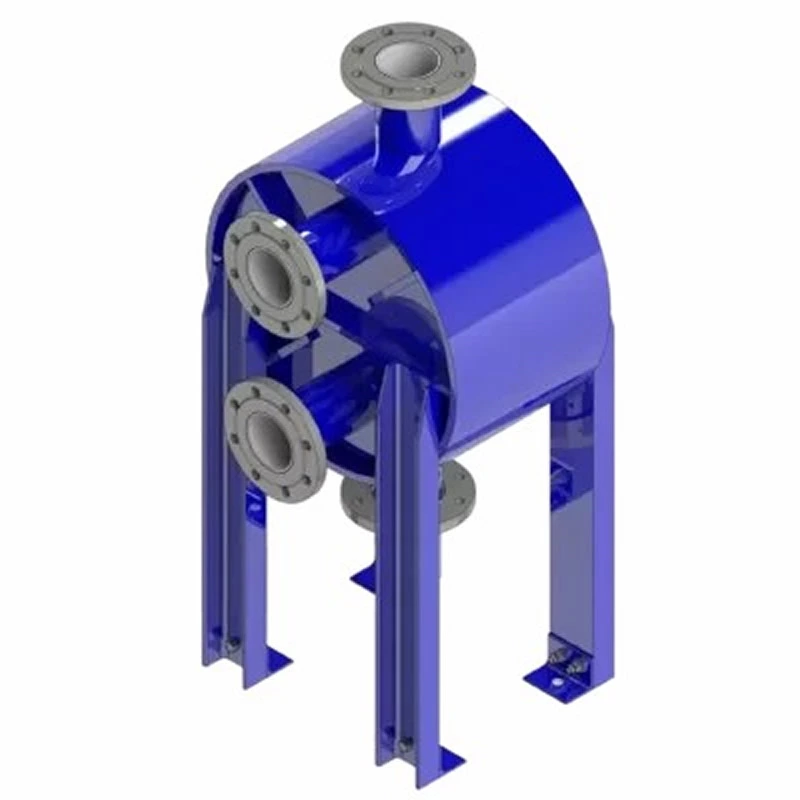

The plate group is then surrounded by a cylindrical shell, similar to that found in a shell and tube heat exchanger. This outer shell provides additional structural support to the plates and helps to create a larger heat transfer surface area. The space between the plates is used to pass one fluid, while the shell side is used to pass the second fluid.

The fluid designated as A passes through the plate side flow channel, while the fluid designated as B passes through the shell side flow channel. The fluids typically flow in opposite directions, which maximizes the temperature difference between the two fluids, and therefore increases the rate of heat transfer.

The flow of the fluids can be either parallel or perpendicular to the plates or shells, depending on the design of the heat exchanger. The plate and shell heat exchanger combines the benefits of plate and tube heat exchangers, making it a more prevalent choice in the heat exchange industry. The plate and shell heat exchanger exists in two categories, the detachable and fully welded models.

The design of a plate and shell heat exchanger allows for a large amount of heat transfer to take place in a compact space. The highly conductive plates allow for efficient heat transfer, while the cylindrical shell helps to distribute the flow of fluids evenly across the plates. Additionally, the design of the plate and shell heat exchanger allows for easy maintenance and cleaning, as the plates can be easily removed for inspection and cleaning.

Plate and shell heat exchanger are used in a variety of applications, including heating and cooling systems, refrigeration systems, and industrial processes. They are particularly well-suited for applications where high heat transfer rates are required in a small space, such as in the oil and gas industry or in the chemical and petrochemical industries.

Please send your information to us and we will give you feedback in time.